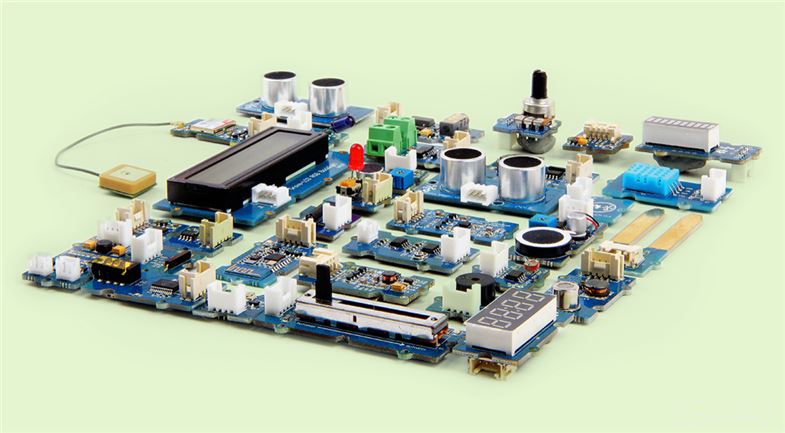

Sourcing of electronic components is a risky management issue for electronics manufacturers, the process consists of long list bill of materials that must be searched. Maintaining electronics components with their up-to-date availability of stock and prices quote is useful and crucial for all electronics engineers when selecting a suitable parts for electronic circuits.

This is becoming a significant risk process that engulfs risk far beyond procurement and reflects on brand total acceptance and reputation.

When technical engineers write to describe each chip datasheet, they rely on electronics parts and a measurement lab that uses a specific, not to say optimized, measurement parameters and testing conditions for analyzing parts manufactured by them which makes technical specifications at online search engines unreliable, risking selection of correct part for electronics designs. Sourcingbot reduces this risk in manufacturing of electronics by providing engineers access to their cross referenced certified lab measurements data regarding parts which engineers use to select the right parts for their designs. They also offer electronics designers with matching engine which looks for the right part according to the required operating point by using machine learning and also suggests alternative suppliers that fits design constraints using prediction models.

Today many electronics components distributors are online which offer huge database of parts for selection and stock information regarding those parts as well as add new electronic parts data to their database daily like Findchips and Octoparts. Although all these electronics components distributors make ordering of parts easy, but Sourcingbot makes ordering parts easier because it is partnered with electronics distributor giants like Mouser Electronics, Element14, Farnell, Avnet and Arrow and along with that it offers search engine with automatic simulation of parts according to required operating point of electronics designers. Automatic simulation is instant solution to limited information of manufactures inaccurate datasheets. Manufacturers like, Murata and Bourn, inductors are found to be deviating from the nominal inductance in inductors datasheets which can cause problems for design engineers and contribute to risk factor.

Time is of great importance to companies and Sourcingbot enables companies to release their product to market faster than their competitors. We spoke to Sourcingbot CEO, Ran Oren about the problem in electronics components sourcing market these days and he said “The problem we see in the market these days is that ‘sourcing world’ relies on datasheets of manufacturers which are not comparable which means sourcing of components still relies on costly and time consuming lab measurements.” Moreover he added “We enable companies to save time to market which reduces the competition for their respective markets.”

With the aim of finally crossing the bridge into the online world, delivering the largest cross reference that relies on physical lab measurements. Large lab measurements acknowledge their sphere is yet another market about to be disrupted by data science and data oriented platforms.

Enabling on demand comparisons.